Innovations in Catalysts and Membranes Set to Transform Water Electrolyser Market

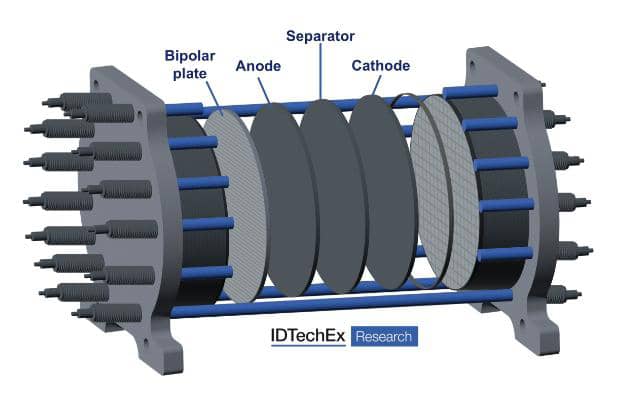

Water electrolysers, the cornerstone technology for producing green hydrogen from renewable electricity, are undergoing a wave of innovation in catalysts and membranes that could dramatically boost efficiency, cut costs, and accelerate adoption worldwide, according to new analysis from IDTechEx.

The research highlights advances across the four main electrolyser types – Alkaline (AEL), Proton Exchange Membrane (PEMEL), Anion Exchange Membrane (AEMEL) and Solid Oxide (SOEC) – each with unique engineering challenges and opportunities.

Alkaline Electrolysers – the most established type – are seeing refinements in nickel-based electrodes, with alloys such as nickel-molybdenum and nickel-cobalt showing strong performance. Manufacturers are experimenting with platinum group metal enhancements and advanced substrates like nickel foam, alongside faster, lower-cost coating methods such as Jolt Solutions’ Sparkfuze process. Diaphragm design is also evolving, with Novamem developing nanoparticle-embedded polymers to improve electrolyte flow.

PEM Electrolysers are benefiting from techniques to reduce iridium usage, a critical step in safeguarding supply chains as demand soars. Companies such as Heraeus are commercialising mixed-metal catalysts to maintain performance while cutting precious metal content. Meanwhile, PFAS-free proton exchange membranes are emerging from innovators like Ionomr Innovations, responding to tightening environmental regulations.

AEM Electrolysers, an emerging hybrid of AEL and PEMEL technology, are moving towards stable hydrocarbon-based membranes free of PFAS. Manufacturers including AGC, Fumatech and Versogen are refining both “wet” and “dry” cathode configurations to maximise efficiency while keeping component costs low.

SOEC Technology, operating at 600–900°C, is leveraging advances from solid oxide fuel cells. New metal-supported cell designs from companies like Ceres Power promise durability and lower material use, while developers such as Topsoe are introducing gadolinia-doped ceria electrolytes to cut operating temperatures and energy consumption.

According to IDTechEx, the annual market for electrolyser components is forecast to exceed US$10 billion by 2036, fuelled by global investment in green hydrogen infrastructure. Even in mature technologies, scope remains for breakthroughs in performance, durability and sustainability.

A full exploration of these trends, market forecasts and leading players can be found in IDTechEx’s latest report, Materials for Green Hydrogen Production 2026–2036: Technologies, Players, Forecasts.